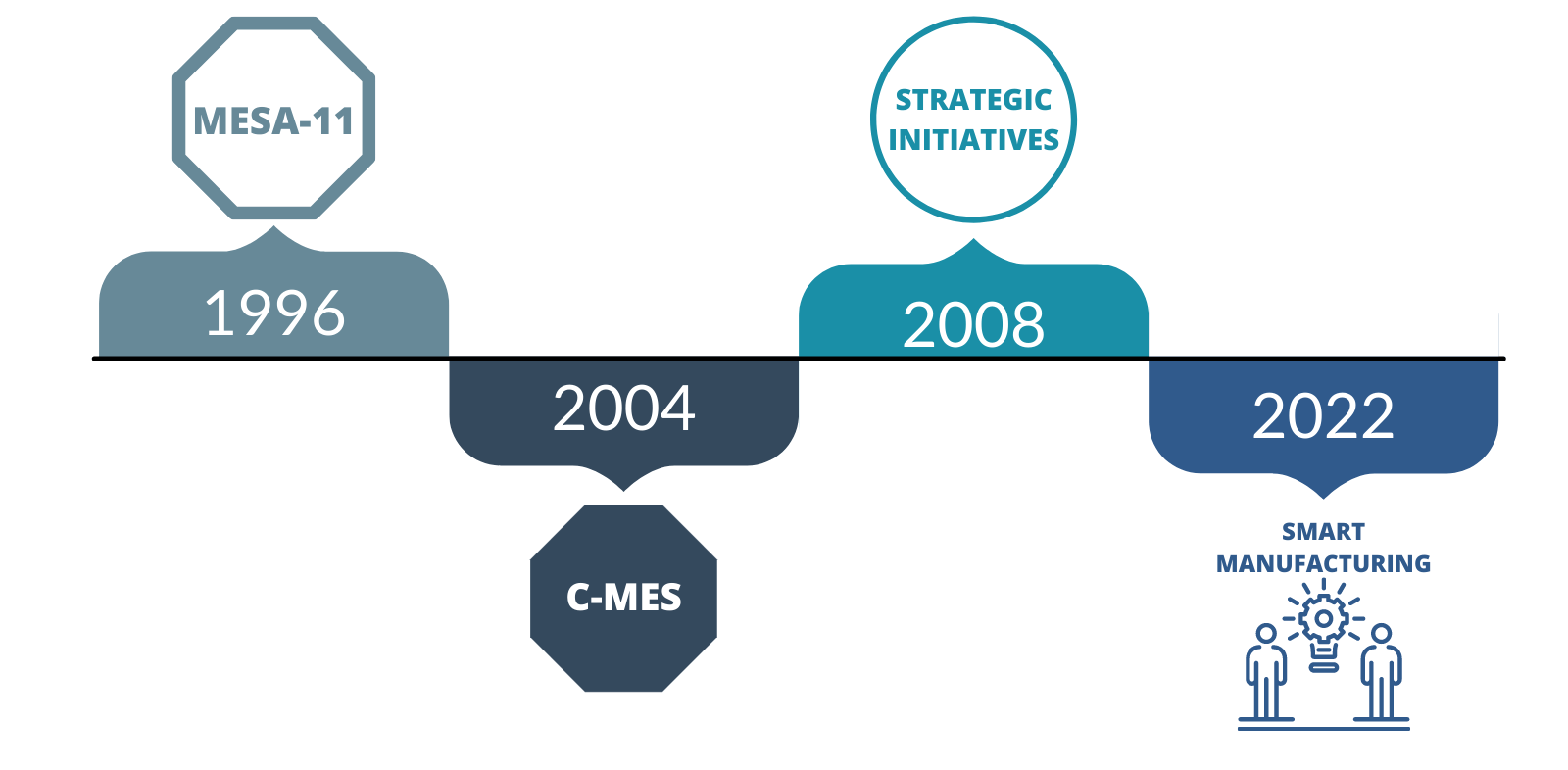

History of the MESA Models

As an educational association, MESA provides models that help those from a variety of levels and disciplines within the manufacturing and production enterprise to converge on common views of what they need to accomplish and how enterprise solutions can assist. The objective is to provide a platform for mutual understanding and planning for increased performance.

To this end, MESA has developed several models over the years with the latest model released in 2022 focused on Smart Manufacturing.

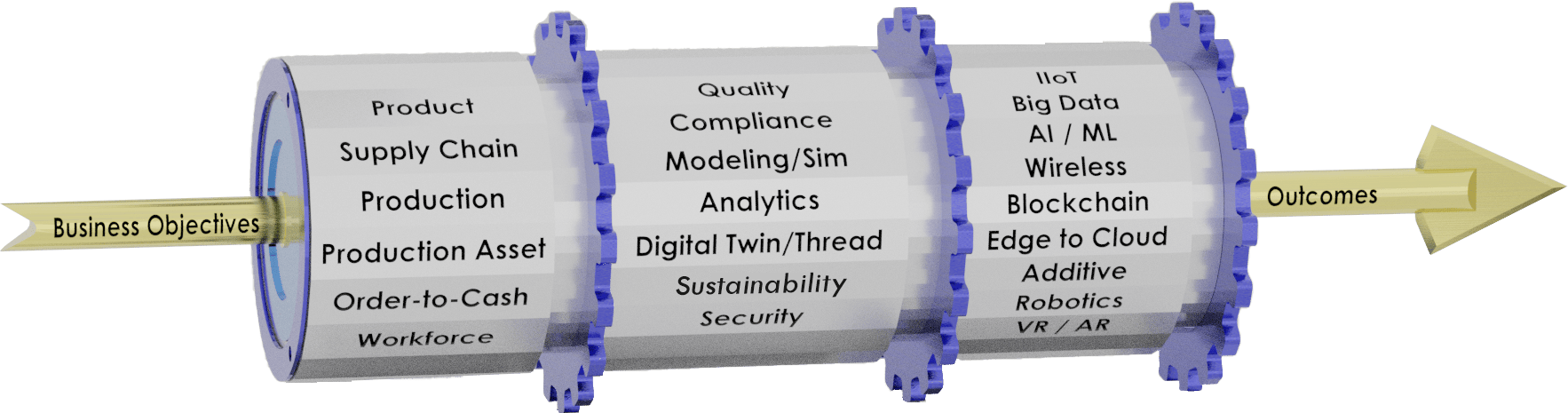

Smart Manufacturing Model

This newest MESA model intends to help define the current and future landscape of Smart Manufacturing and production. It considers concepts that have been a part of manufacturing and production forever, but dives deeply into how these concepts are made “smart” by integrating related functions and incorporating new or advanced technology. It focuses on Lifecycles, Cross-Lifecycle Threads and Enabling Technologies. The model is intended to evolve as new technologies and capabilities emerge.

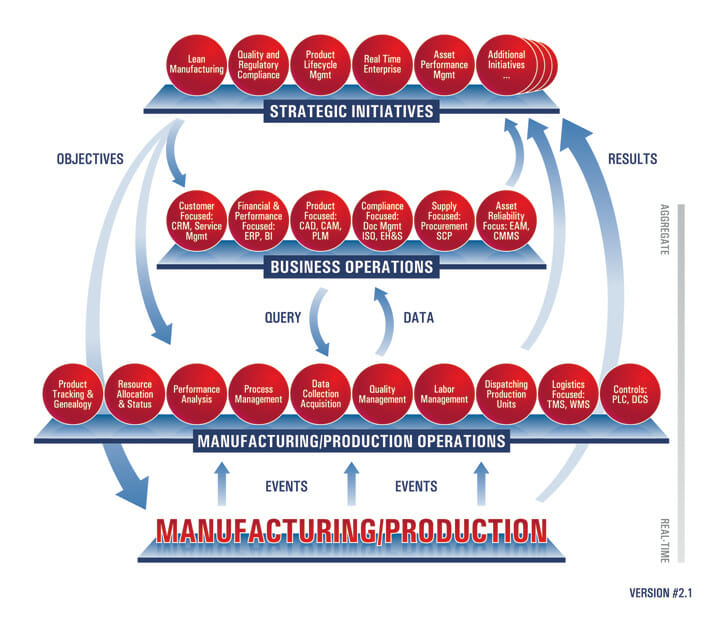

Strategic Initiatives Model

The Strategic Initiatives Model, developed in 2008, spans from enterprise-level strategic initiatives to business operations to plant operations and actual production. It shows the interrelationships between strategies, enterprise-level operations, and plant operations. Objectives cascade down, and results are reported up against those objectives. It also provides a conceptual illustration of how events in the plant operation feed and inform all other events, and how aggregate views from the enterprise can drill down through operations to the real-time production views.

Along with this model, MESA published seven (7) Strategic Initiatives Guidebooks. The relentless focus on operational improvement and corporate compliance has elevated the need for new and enhanced ways to drive more value from existing assets, and it's become increasing clear that a better, more systematic flow of information from the operation is key to enabling and accelerating those initiatives. MESA's intent is to help manufacturers successfully create justification for, implement and then measure the impact of a series of strategic corporate initiatives in this area. These Guidebooks consist of a holistic set of pragmatic guidance and best practices to both, educate key stakeholders and to identify & address key issues related to the successful implementation of these initiatives.

The MESA Strategic Initiatives are the following:

- Asset Performance Management (APM)

- Lean Manufacturing

- Product Lifecycle Management (PLM)

- Quality and Regulatory Compliance

- Real-time Enterprise

- Manufacturing Performance Metrics

- Return on Investment (ROI)

The major components of each of the Guidebooks include: Problem Definition, Cost Justification and ROI development, Project Critical Dependencies, Implementation Guidance, Risk Assessment and Success Criteria and Measurements.

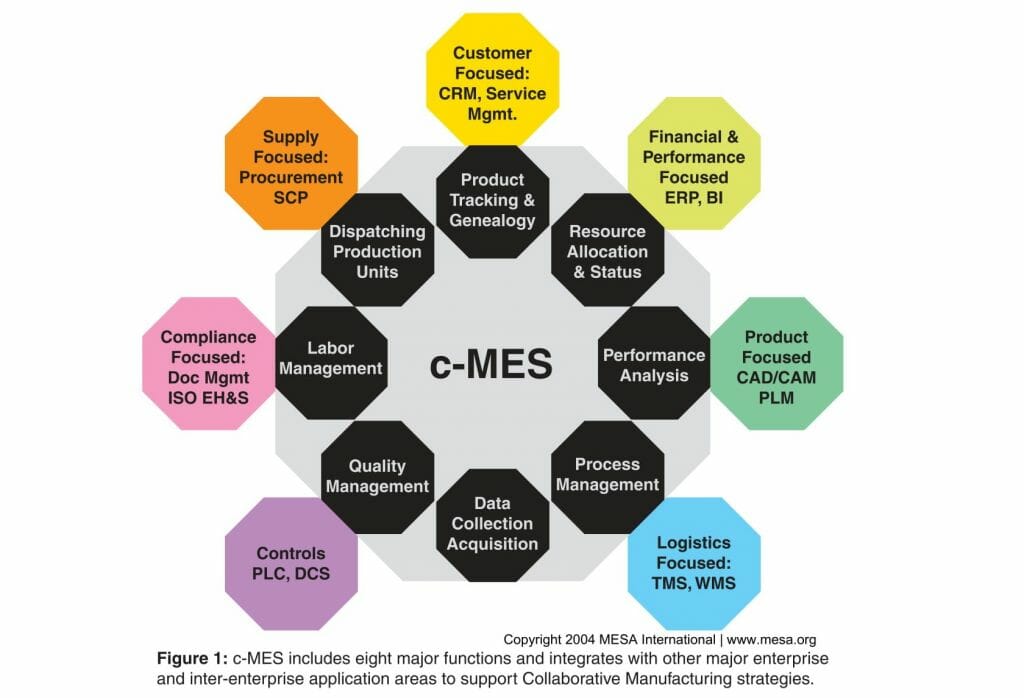

C-MES Model

Previous versions of the MESA model focused exclusively on operations (as did the organization itself at the time). The Collaborative MES or C-MES model from 2004, focused on how core operations activities interact with business operations in a model that represented issues such as increased competition, outsourcing, supply chain optimization, and asset optimization. Inside the c-MES box, the model depicts functions typically found in the integrated MES product offerings at that time. The c-MES world then interfaces to the other business operations areas around the edges.

MESA White Paper #8 outlines the objectives of this model: "What characterizes Collaborative Manufacturing Execution Systems (c-MES)? These systems combine earlier generation MES functionality to operate and improve plant operations and add better ability to integrate with other systems and people in the enterprise and value chain/stream. Although some of this data has been shared through traditional communications, the Internet and web-based technologies such as XML and web services provide a significant leap in accuracy and timeliness of communications."

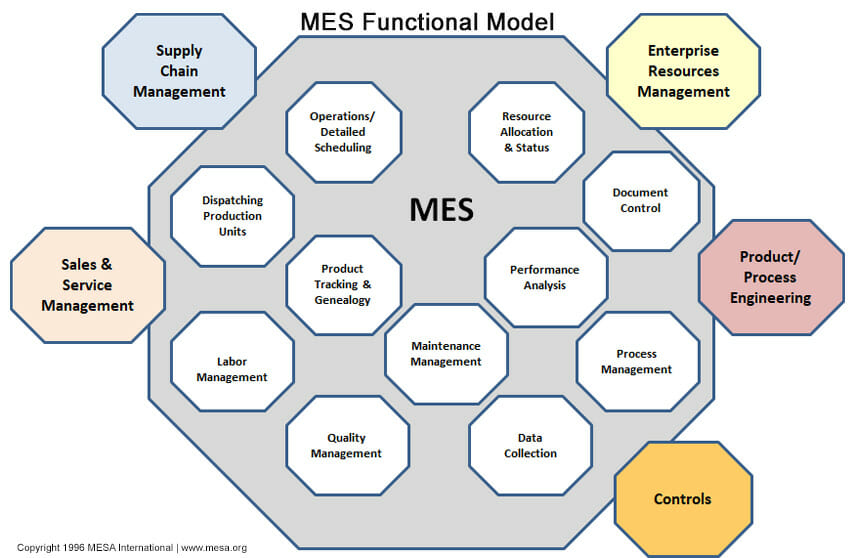

MESA-11 Model

The original "MESA-11" model was published in 1996. This model indicated 11 core functions of a manufacturing execution system with relationships to external enterprise systems and functional areas. This model depicts what, at the time, was the MESA view of the functions within a manufacturing execution system, including scheduling and sequencing, maintenance, and quality.

Additional Resources

White Paper

#39: MESA Model Evolution

This paper describes the evolution of the MESA Model from the MESA Functions originally developed and published in 1992 to the Context Model of 1996, the Collaborative Model of 2002 and the Strategic Initiatives Model developed in 2008.

PRESENTATION

MESA Model Framework for Smart Manufacturing

What benefits does the new MESA model offer for your business?

PORTAL

Online Learning & Resource Center

View all the MESA Model content in the Online Learning & Resource Center.